Platinum vs Tin Cure Silicone: Which is Right for Your Project?

You’re about to invest time and effort into a mold-making project, but one big decision stands in your way: choosing between platinum-cured silicone and tin cure silicone.

The silicone you select can make or break the results. Platinum cure silicone is all known as the food-safe, highly durable, and long lasting. while Tin cure silicone is more affordable, flexible, and friendly for beginner

If you’re a new or mid-level mold maker, proper guidance is essential for picking the right material. That’s why this guide carefully breaks down platinum silicone vs tin cure silicone, their benefits, key differences, and ideal applications.

To make your choice even simpler, you’ll also find a convenient comparison table included.

What Does Platinum Cure Silicone Mean? 1

Important Differences Between Silicone Cure Tin and Platinum 2

Factors of Technical Influence on Your Choice 4

When to Use Platinum Cure Silicone 4

When to Use Tin Cured Silicone 5

Platinum vs Tin Cure Silicone Summary 5

From Facts to Function: Your Next Step 6

What Does Platinum Cure Silicone Mean?

Platinum cure silicone ( it also called addition-cure silicone) is a two-part RTV (room temperature vulcanizing) silicone rubber that Platinum catalyzes. Normally, the mixing ratio is based (Part A) with the catalyst (Part B) in ratios like 1:1 or 10:1.

Once combined, it cures into a tough, flexible mold.

- Tear strength: Platinum treatment silicone is very immune to tearing, making it excellent for complex mold and mildews with deep undercuts. With a tear toughness of 100– 200pil and also , it permits the launch of extremely detailed parts without damages.

- Long Life: Properly keep stored, these molds can last for decades. Many makers said that platinum cure molds still used nicely after 20 years. That long shelf life makes them ideal for producing museum-quality pieces.

- Food-Safe: it’s food grade silicone, it means they’re safe for cooking applications such as chocolate molds, candy molds,sweet mols and mildews and other food-contact products.

- Superior Heat Resistance: The temperature resistance is from -40°C up to 230°C. it is good for casting resins and even some low melting metals.

With above strengths, platinum cure silicone is also widely used for prosthetics, special effects, and other professional applications. The downside? it’s cost higher than tin cure and it can be sensitive to cure inhibition.

Still, when precision and durability matter, it’s often worth the investment. Learn about our platinum cure silicone products to use on a project.

What is Silicone Tin Cure?

Tin-cure silicone, also called condensation cure silicone, is another two-part RTV material. It uses a tin-based catalyst to cure. The process is simple: mix the base and catalyst in ratios like 10:1 (base:catalyst), 4:1, or even 1:1. Once combined, it cures into a flexible mold.

This is what makes it unique:

- Cost-Effective: Tin cure is about 30–50% cheaper than platinum cure. That makes it a smart choice for large molds or one-off projects where cost matters.

- Less Prone to Cure Inhibition: With proper sealing, it cures reliably on most surfaces. Even tricky materials, like sulfur-based clays, are less of a problem. This makes it more forgiving for beginners.

- Easy Mixing: Ratios are straightforward, and it offers a enough working time of 15–30 minutes. it gives you room to mix, pour, and adjust without rushing.

Tin-cure silicone will be used when applying general-purpose molds, prototyping, or a short-term project.

It has a lower tear strength (50-100 pli) and less heat resistance (up to 350°F), but it is versatile compared to platinum. You can check out our tin-cure silicone products, which are reasonably price.

Alt Text: Photorealistic close-up showing the mixing process for tin-cure silicone, part of a platinum vs tin cure silicone comparison, with a gloved hand pouring TIn blue catalyst

Important Differences Between Platinum Vs Tin Cure Silicone

You should know the main distinctions between platinum v. tin cure silicone to make a better decision. Let’s compare in detail:

Cure Inhibition

Platinum cure silicone is sensitive to contaminants like sulfur, latex, or certain resins. If exposed, the mold may stay tacky or fail to cure completely. This is why a clean workspace is essential.

Tin cure silicone is more forgiving. It cures reliably on most surfaces as long as basic preparation is done. That makes it easier for beginners or anyone working in less controlled environments.

For a deeper explanation of inhibition and materials to avoid, see this detailed guide from TechSil.

Cost

Platinum cure silicones are more expensive because of their platinum catalyst. They typically cost $50–100 per gallon.

Tin cure silicones, on the other hand, are much cheaper, around $20–40 per gallon. This price gap makes tin cure the practical choice for low-budget projects, large molds, or disposable molds.

Shelf Life

Platinum cure silicone has near-zero shrinkage (about 0.1%). This allows it to preserve fine details and maintain precision over time. Tin cure silicone shrinks slightly more (about 0.3–0.5%). While minor, this can affect accuracy in long-term or high-detail projects.

Shrinkage

Silicone cap-less platinum has zero and even less (≈ 0.1%) shrinkage to hold the accuracy of a finer cast. The tin-cure silicone contraction is slight (≈ 0.3–0.5%), which can be a problem in the long run compared to accuracy.

Applications

Platinum cure silicone is best for food-safe molds, prosthetics, and projects where accuracy matters. Tin cure silicone works well for general-purpose molds, prototypes, or one-off projects where cost is more important than precision.

Factors Of Technical Influence On Your Platinum Vs Tin Cure Silicone Choice

- Tear Strength: Platinum (100-200 pli) to Tin (50-100 pli). Better tear strength leads to more durable molds; you always need more durable molds when you are demolding over and over.

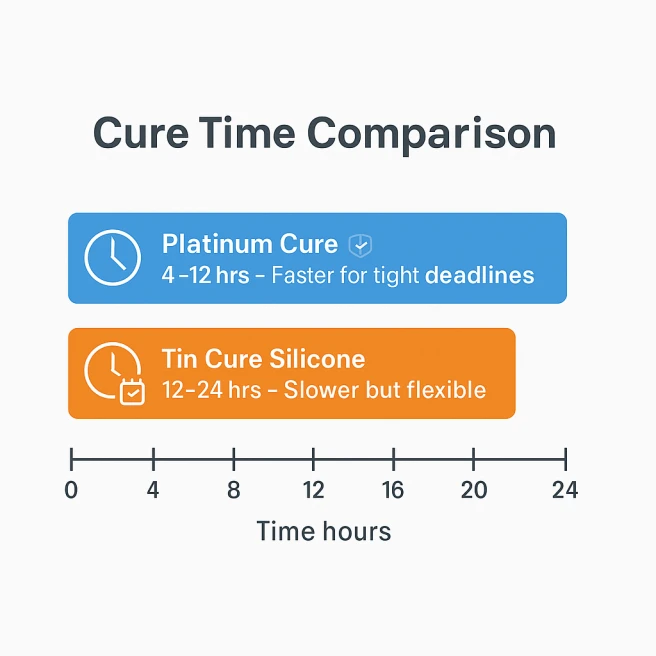

- Cure Time: Platinum (4-12 Hours), Tin (12-24 Hours). Quicker curing gives you when you are on strict deadlines.

Alt text: Square horizontal bar chart comparing cure times for platinum vs tin cure silicone, with a blue bar for platinum cure labeled “4–12 hrs – Faster for tight deadlines” and an orange bar for tin cure silicone labeled “12–24 hrs – Slower but flexible,” displayed over a 0–24 hour time scale.

- Viscosity: 10,000–50,000 mPa·s (platinum) and 15,000–40,000 mPa·s (tin). Reduced viscosity provides a good flow to intricate details, which influence the quality of the molds.

Such differences will help you determine your choice on project requirements and budget.

When to Use Platinum Cure Silicone

Platinum cure silicone is the type you will use in making projects that require durability, safety, or precision. Here is where it excels:

- FDA-Compliant Molds:

Perfect for food applications such as baking, chocolate, or candy molds. Platinum-cure silicone meets FDA standards, making it safe for direct food contact.

- Prosthetics and Special Effects:

In film, theater, and medical settings, skin-safe materials are essential. Platinum cure silicone has a realistic texture, is long-lasting, and is certified for direct skin contact. That’s why it’s a standard in prosthetic and special effects work.

- Long Shelf Life:

When stored properly, molds made from platinum cure silicone can last for decades. This makes it ideal for museum pieces, production runs, or any project where longevity matters.

Tips:

- Use non-sulfur-based clays or non-latex gloves to avoid cure inhibition.

- It is applied in high-temperature casting, such as low-melting metals (up to 450°F).

- Molds should be kept in a dry, cool store to enhance durability.

Platinum-cured silicone is favored over tin-cured silicone in high-end uses. Find out decomposing skills in our Ultimate Guide to Mold Making in Silicone.

When to Use Tin Cured Silicone

You will love Tin-cure silicone when using low-cost or light implementation projects. The following are the guidelines for its use:

- General-Purpose Molds: If you are casting resin, plaster, or concrete and wish to make decor items or prototypes, this tin-cure silicone can help you do the job.

- One-Off Projects: Its price is economical for one-time molds, such as art installations.

- Inhibition of Cure Issues: When used with sulfur-loaded clays or 3D printed resin masters, tin-cure silicone will cure effectively with a sealing agent.

Tips:

- Use a release agent/ sealant on tricky surfaces so that curing can take place.

- Apply in large-sized molds where cost is a preference.

- Non-critical dimensions expect a shrinkage of 0.3%.

Comparing platinum and tin-cure silicone, the latter is cheaper and has more applications, making it suitable for beginners. Check our tin-cure silicone products to get the one you need for your next project.

Platinum vs Tin Cure Silicone Summary

In order to make a quick comparison of platinum vs tin cure silicone, here is what you should know:

| Feature | Platinum Cure Silicone | Tin Cure Silicone |

| Cost | High ($50-$100/gallon) | Low ($20-$40/gallon) |

| Cure Inhibition | Sensitive to sulfur, latex | Less prone, cures with sealing |

| Shelf Life | Decades | 1-5 years |

| Shrinkage | Near-zero (0.1%) | Slight (0.3-0.5%) |

| Tear Strength | High (100-200 pli) | Moderate (50-100 pli) |

| Heat Resistance | Up to 450°F | Up to 350°F |

| Food Safety | FDA-compliant options available | Not food-safe |

| Best Applications | Food-grade prosthetics, long-term molds | General-purpose, one-off molds |

From Facts to Function: Your Next Step

Now you know the main differences between platinum and tin cure silicone. Platinum cure silicone is strong, food-safe, and precise. It’s the right choice for prosthetics, pastry molds, and other high-end projects.

Tin cure silicone is cheaper and easier to use. It’s best for general-purpose molds or one-time jobs. Think about your budget. Think about your project goals. Consider how long you want the mold to last. Choose platinum cure if you need durability and food safety. Choose tin silicone if you need a quick, low-cost prototype.

Are you ready to start your next mold-making project?

Pls log the TopSil Silicone collection to chose the right fit, or any your questions pls contact whatsapp: +86-18576775369; Email: [email protected]