Superior Silicone Rubber for GRC/GFRC Mold Making: Precision and Durability

In the demanding fields of Glass Fiber Reinforced Concrete (GFRC), Glass Fiber Reinforced Gypsum (GRG), and Glass Reinforced Concrete (GRC) production, the quality of your molds is paramount. As a leading manufacturer of silicone rubber, RTV silicone, liquid silicone, RTV2 silicone, molding silicone, mold making silicone, and platinum silicone, we offer specialized solutions tailored to the unique needs of GRC product factories, GRC molding factories, GFRC mold making, and GRG mold making. Our silicone rubber for GRC and GFRC applications delivers exceptional performance, ensuring precise detail reproduction, superior durability, and ease of use. By choosing to source directly from our manufacturing plant, you gain access to premium-grade silicone base materials at competitive prices, backed by expert technical support to optimize your GRC mold making production.

Silicone Rubber: The Ideal Choice for Demanding GRC/GFRC Applications

Silicone rubber has emerged as the preferred mold-making material in the GRC/GFRC industry due to its unique combination of properties. Our silicone rubber formulations, specifically designed for GRC and GFRC, offer exceptional tear strength, flexibility, and resistance to the alkaline nature of concrete and gypsum. This ensures your molds can withstand the rigors of repeated casting cycles while maintaining dimensional accuracy and intricate detail reproduction.

Our liquid silicone rubber options, including RTV-2 silicone rubber, provide excellent flowability, allowing the silicone to penetrate every detail of your master model. This is crucial for capturing the complex shapes and textures often found in architectural GRC/GFRC elements using silicone base materials. We offer tin cure silicone rubber that is good for a wide range of products, and our platinum cure silicone rubber offers food-safe options for high temperature applications. Our silicone rubber can be used to make molds for a wide variety of applications, including those that require products and therefore multiple-piece molds. silicone for concrete and stone molding.

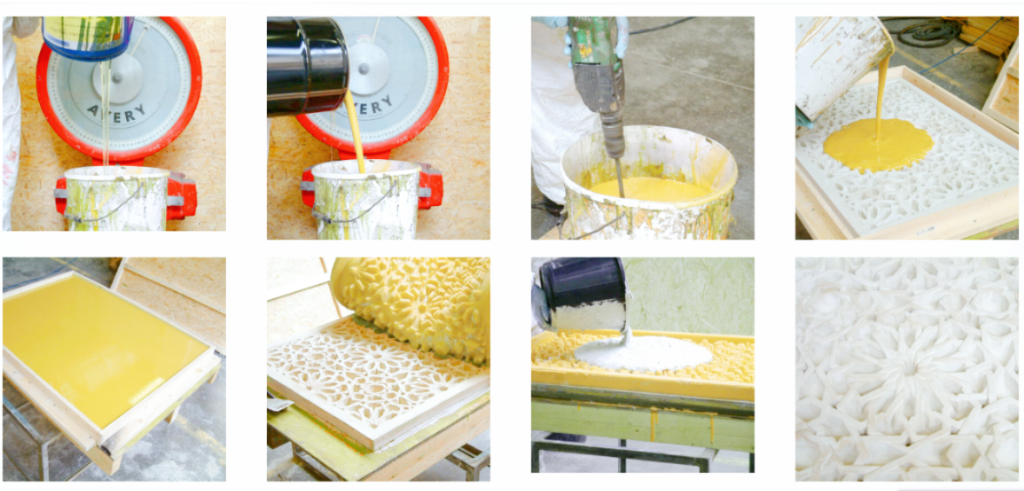

Liquid Silicone Rubber for making various products.: Optimizing the GRC/GFRC Molding Process

Our liquid silicone rubber for GRC is a game-changer for manufacturers seeking to enhance efficiency and precision in their molding process. The low viscosity of our liquid silicone allows it to flow effortlessly around complex shapes and intricate details, ensuring complete mold coverage and accurate reproduction of the original pattern.

We offer both tin cure and platinum cure liquid silicone rubber options. Tin-cured silicone rubber provides a cost-effective solution with good overall performance for GRC mold making. Platinum-cured silicone rubber, while sometimes a higher initial investment, offers superior heat resistance, longer mold life, and excellent chemical resistance. The choice between tin cure and platinum cure as a curing agent depends on your specific application requirements and budget considerations. We also have materials that work well for silicone for resin mold making.

Tailored Solutions for GFRC Molding and Plaster Molding

GFRC molding and plaster molding each present unique challenges that our silicone rubber solutions are designed to address with temperature curing silicone mold materials. For GFRC molding, our silicone rubber’s high strength and resistance to abrasion ensure molds can withstand the weight and texture of glass fiber-reinforced concrete. The flexibility of our silicone also facilitates easy demolding, even with complex GFRC panel designs.

In plaster molding, our silicone rubber’s excellent detail reproduction and smooth surface finish ensure that even the most delicate gypsum products are faithfully replicated. Our silicone’s resistance to moisture prevents warping or distortion of the mold, ensuring consistent results over time. Our silicone rubber is also used in high temperature applications. silicone for shoe mold making due to its excellent detail reproduction.

Useful Information:

- Technical Data Sheets: Each of our silicone rubber products comes with a comprehensive technical data sheet, providing detailed specifications on viscosity, cure time, hardness (Shore A), tear strength, and mixing ratios.

- Usage Instructions for RTV2 silicone rubber: We offer clear, step-by-step instructions and video tutorials to guide you through the mold-making process, ensuring optimal results with our silicone rubber.

- Environmental Considerations: We are committed to sustainable manufacturing practices and offer environmentally friendly silicone options.

- Customer Testimonials: Many have found that RTV silicone rubber significantly enhances their molding projects. Hear from other GRC/GFRC manufacturers who have successfully integrated our silicone rubber into their production processes. Their experiences highlight the real-world benefits of our products.

Internal Links (Examples): silicone rubber for making molds.

- Explore our diverse range of RTV-2 mold making silicone rubber. RTV silicone products for GRC/GFRC mold making.

- Discover the advantages of liquid silicone for complex GRC/GFRC designs using high-quality molding silicone rubber.

- Learn more about our mold making silicone rubber. platinum cured silicone options for demanding applications.

- Find the perfect silicone rubber for your specific GRC/GFRC molding needs.

- Master the art of silicone mold making with our expert resources.

- Contact our technical team for personalized guidance and support on molding silicone rubber.

Example Table:

| Silicone Type | Hardness (Shore A) | Cure Time (Room Temp) | Tear Strength | Applications |

| Tin Cure RTV Silicone | 20-40 | 12-24 hours | High | General GRC/GFRC molds, cost-effective options with room temperature curing silicone mold materials. |

| Platinum Cure Silicone | 10-50 | 2-6 hours | Excellent | High-detail GRC/GFRC molds, long-lasting molds |

| Liquid Silicone Rubber | 5-80 | Variable | Very High | Intricate designs, complex shapes, flexible molds |

Example Quote: Our silicone rubbers may be necessary for specific applications.

“Using this silicone rubber has significantly improved the quality of our GFRC panels and reduced our mold replacement costs.” – John D., GFRC Production Manager

Here’s a conceptual bar chart and example data to illustrate the superior lifespan of silicone rubber molds in GRC/GFRC production.

Chart Title: Mold Lifespan Comparison in GRC/GFRC Production

X-Axis (Horizontal): Mold Material (Categories)

- Plaster Molds

- Polyurethane Rubber Molds

- Standard Silicone Rubber Molds

- RTV2 Tin Cure Silicone Molds

- RTV2 Platinum Cure Silicone Molds

Y-Axis (Vertical): Average Number of Castings (Mold Lifespan)

Data (Example – Adjust these based on your actual data):

| Mold Material | Average Number of Castings |

| Plaster Molds | 5-15 |

| Polyurethane Rubber Molds | 50-100 |

| Standard Silicone Rubber Molds | 100-200 |

| RTV2 Tin Cure Silicone Molds | 200-400 |

| RTV2 Platinum Cure Silicone Molds | 400-800+ |

Chart Description:

The bar chart will visually demonstrate the significant differences in lifespan between various mold materials used in GRC/GFRC production. It will clearly show that silicone rubber molds, particularly RTV2 Platinum Cure Silicone molds, offer the longest lifespan and therefore the best value over time.

Summary of Advantages for Topsil Silicone for GRC/GRG Mold Making:

Elevate your GRC/GFRC production with our durable, high-detail silicone rubber molds. Experience easy demolding, exceptional tear strength, and expert support. Contact us today for the perfect molding solution!