Revolutionize Composite Manufacturing with Reusable Silicone Vacuum Bags

In the rapidly evolving world of composite manufacturing, efficiency, cost-effectiveness, and quality are paramount when using our vacuum bags for producing composite. As a leading producer of vacuum bag silicone, vac bag silicone, silicone rubber, RTV silicone, liquid silicone, RTV2 silicone, and silicone for reusable vacuum bags, we offer cutting-edge solutions tailored to the needs of fiberglass composite factories, vacuum casting factories, 3D printing factories, RTM infusion molding factories, and LRTM infusion in closed mold processes. Our EZ-Brush Vac Bag Silicone, a brushable platinum cure silicone developed especially for making high-performance reusable vacuum bags, delivers exceptional durability, ease of use, and rapid production capabilities. By choosing our silicone solutions, you gain a competitive advantage through streamlined processes, reduced labor costs, and superior composite part quality. Our silicone is also effective in creating a Our silicone for rapid prototyping molding delivers a production ready silicone.

The Advantages of Reusable Silicone Vacuum Bags

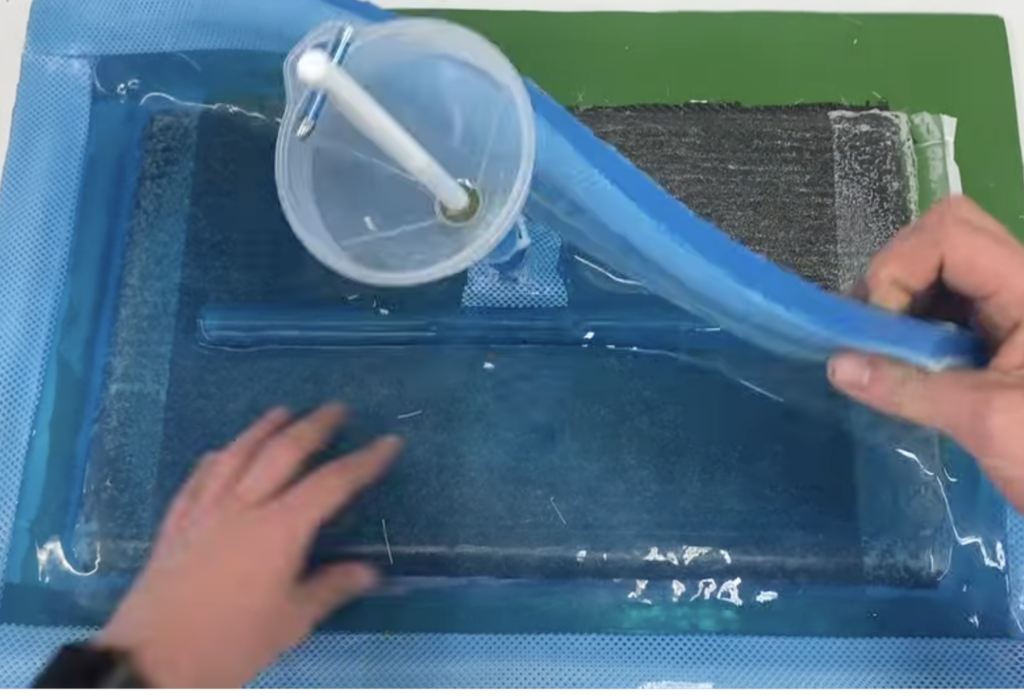

Reusable silicone vacuum bags, developed especially for making high performance composites, offer numerous advantages over traditional vacuum bagging methods. Our bag silicone is much faster at delivering a production-ready silicone bag, resulting in tremendous time and labor savings compared to conventional vacuum bagging. The flexibility and durability of our silicone bags allow for repeated use, significantly reducing consumable costs associated with traditional disposable bagging materials.

Furthermore, silicone vacuum bags provide superior conformability to complex shapes and intricate mold details, ensuring consistent vacuum pressure distribution across the entire part during the resin infusion or curing process. This results in higher quality composite parts with fewer defects, such as voids or resin-starved areas. If you’re looking for other options, we also offer silicone for vacuum bag casting.

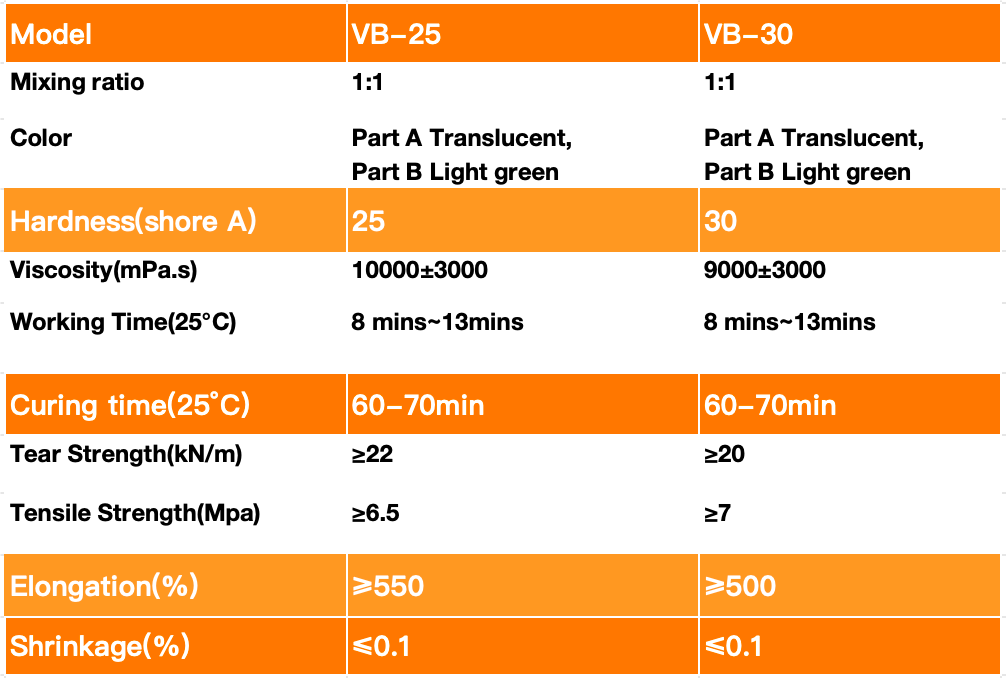

Data Sheet of Vacuum Bag Silicone

Brushable Platinum Silicone Rubber: Simplifying Vacuum Bag Fabrication

Our EZ-Brush Vac Bag Silicone is a brushable platinum silicone rubber specifically developed for creating durable, high-performance, re-usable vacuum bags. This innovative silicone is easy to mix and apply, requiring no specialized spray equipment. The silicone rubber can be applied with a brush or spatula to vertical surfaces without sagging, allowing for precise control over bag thickness and shape. It cures with negligible shrinkage to a soft, flexible rubber, ensuring a perfect fit to your mold.

Compared to traditional vacuum bagging techniques, using our brushable silicone, such as EZ-Brush Vac Bag, significantly reduces the time and labor required to produce a vacuum bag. This accelerated process, using advanced vacuum bagging materials, allows for faster production cycles and quicker turnaround times, giving you a competitive edge in the fast-paced composites industry.

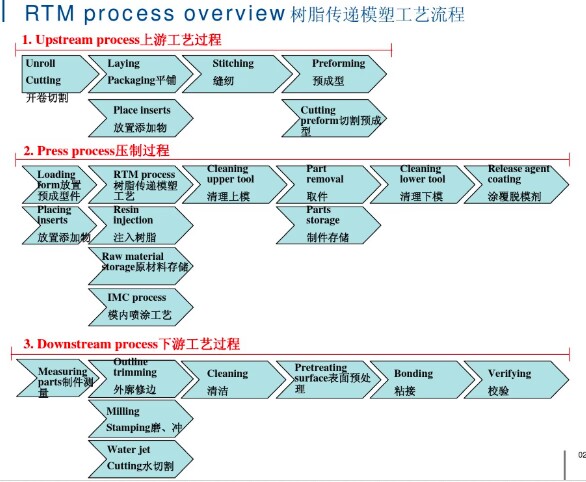

Optimizing Resin Infusion and Composite Part Production

Our silicone vacuum bags are designed to enhance resin infusion processes, including RTM and LRTM, by providing a reliable and consistent vacuum seal. The flexibility of the silicone bag ensures uniform pressure distribution, promoting even resin flow and minimizing voids in the finished composite part. The high tear strength and durability of our silicone allow the bags to withstand multiple cure cycles, making them a cost-effective solution for producing composite parts.

In addition to resin infusion, our silicone vacuum bags are also suitable for use with prepreg materials and in various composite molding processes. Their high-temperature resistance, up to 260°C, makes them compatible with a wide range of curing cycles. Our silicone bags have proven popular with factories looking to make a vacuum bag resulting in a tremendous efficiency boost. silicone for shoe mold making.

Useful Information:

- Technical Data Sheets: Each of our silicone products comes with a detailed technical data sheet, providing specifications on viscosity, cure time, hardness (Shore A), tear strength, and mixing ratios.

- Usage Instructions: We provide clear, step-by-step instructions and video tutorials to guide you through the process of creating and using our silicone vacuum bags.

- Environmental Impact: Our reusable silicone vacuum bags are an eco-friendly alternative to disposable bagging materials, reducing waste and promoting sustainable manufacturing practices.

- Customer Reviews: Hear from other composite manufacturers who have successfully integrated our silicone vacuum bags into their production processes.

Internal Links :

- Explore our range of silicone rubber products for composite manufacturing.

- Discover the benefits of liquid silicone for vacuum bag molding with Reynolds Advanced Materials.

- Learn more about our RTV silicone options for various molding applications.

- Find the perfect silicone for your specific vacuum bagging needs.

- Enhance your expertise with our resources on silicone 20 and vacuum bagging materials. vacuum bag silicone.

- Contact our technical team for personalized guidance and support, especially for making high performance applications.

Production ready silicone bag results for various applications.

| Property | EZ-Brush Vac Bag Silicone | Traditional Bagging Film |

| Material Cost | High-quality | Lower initial cost |

| Labor Cost | Significantly reduced | Higher |

| Reusability | Reusable (multiple cycles) | Disposable (single-use) |

| Cure Time | Faster | Longer |

| Conformability | Excellent | Limited |

| Durability | High | Low |

| Environmental Impact | Lower (less waste) | Higher (more waste) |

Example Quote:

“Switching to these silicone vacuum bags has revolutionized our production process. We’ve reduced labor costs, minimized waste, and improved the quality of our composite parts.” – Mark R., Composites Engineer

Cost Savings Over Time: Reusable Silicone Vacuum Bags vs. Traditional Disposable Bags

| Number of Cycles | Traditional Bagging Cumulative Cost (USD) | Reusable Silicone Bag Cumulative Cost (USD) |

| 1 | 50 | 250 |

| 10 | 500 | 300 |

| 20 | 1000 | 350 |

| 30 | 1500 | 400 |

| 40 | 2000 | 450 |

| 50 | 2500 | 500 |

| 100 | 5000 | 750 |

Summary of Advantages :

Our reusable silicone vacuum bags reduce labor, minimize waste, and enhance composite part quality. Experience faster production cycles and superior results. Contact us for a cost-effective solution!