Advanced Silicone for Prosthetics: Elevate Your Manufacturing Process

In the world of prosthetics, the quality of materials used can significantly impact the comfort and functionality of the end product. Our platinum silicone, soft silicone, and a variety of specialized silicone products such as RTV silicone, liquid silicone, and RTV2 silicone are designed to meet the highest standards of durability and comfort. Whether you are a prosthetic product manufacturer, an orthotic factory, or a silicone prosthetic products manufacturer, our solutions offer reliability and innovation to enhance your production processes and improve user satisfaction.

Why Choose Our Silicone for Prosthetics?

Developing high-quality prosthetics requires materials that offer exceptional performance, comfort, and durability. Our proprietary silicone for prosthetics formulations provide the ideal solution for creating lifelike and functional prosthetic devices. Here’s why you should consider partnering with us: we specialize in high-grade silicones in prosthetics.

- Superior Flexibility: Our soft silicone ensures a comfortable fit and adapts seamlessly to the contours of the human body.

- Durability and Longevity: Made from silicone elastomers, our products maintain their integrity under extensive use, reducing the need for frequent replacements.

- Realistic Appearance: Our flesh-tone silicone can also be used in special effects applications. options provide natural skin tones, enhancing the aesthetic appeal of prosthetic devices.

- Customizable Solutions: We offer silicone for molds and

prosthetic moldstailored to your specifications, allowing for bespoke prosthetic designs. - Eco-Friendly and Safe: Our materials are of excellent grade, ensuring the best performance in silicone based applications. safe for skin and environmentally friendly, ensuring user safety and sustainability.

Key Feature silicone based appliances that provide excellent comfort and durability.s of Our Silicone for Prosthetics

Flexible and Durable Silicone Elastomers

Our silicone elastomers are specifically engineered to meet the demanding needs of prosthetic manufacturing. Their unique properties provide the perfect balance between flexibility and strength, crucial for developing prosthetics that enhance the user’s quality of life.

- High Tear Strength: Ensures that prosthetic components resist tearing and deformation, even under rigorous use.

- Excellent quality of life improvements are achieved with our silicone based solutions. Flexibility: Offers natural movement and comfort, supporting seamless integration with the user’s body.

- Heat Resistance: Withstands high temperatures during manufacturing, ensuring that the silicone maintains its integrity throughout the production process.

Explore our Silicones for Prosthetic Application for durable and versatile prosthetic solutions.

Customizable Mold Making with Silicone Rubber

Our range of silicone rubber solutions supports intricate silicone gels in prosthetics mold making, enabling manufacturers to create prosthetic devices with precision and detail. Our products facilitate the production of realistic and functional prostheses that cater to a variety of user needs.

- Custom Mold Designs: Achieve accurate replication of anatomical features, enhancing the wearer’s experience and device efficiency.

- Pigment Integration: Easily integrate pigments to match skin tones and achieve a natural appearance for prosthetic components.

- Versatility in Use: Suitable for producing a wide range of prosthetic items, from gloves to prosthetic liners.

Leverage our Silicone for Vacuum Bag Casting to streamline your prosthetic manufacturing processes.

Superior Adhesives and Sealants for Security

For prosthetic devices, adhesion is critical to ensure stability and comfort. Our silicone adhesive products provide the necessary bond to secure prosthetics without compromising comfort or flexibility.

- Strong Adhesion: Provides a reliable hold that keeps prostheses securely in place, ensuring user confidence and comfort.

- Skin-Friendly: Our adhesives are formulated to be safe for skin, minimizing the risk of irritation and enhancing user comfort.

- Ease of Application: Compatible with various surfaces, our adhesives simplify the application process, increasing production efficiency.

Discover how our silicone based products can enhance your experience. Antistatic Pad Printing Silicone can enhance your prosthetic production with superior adhesives.

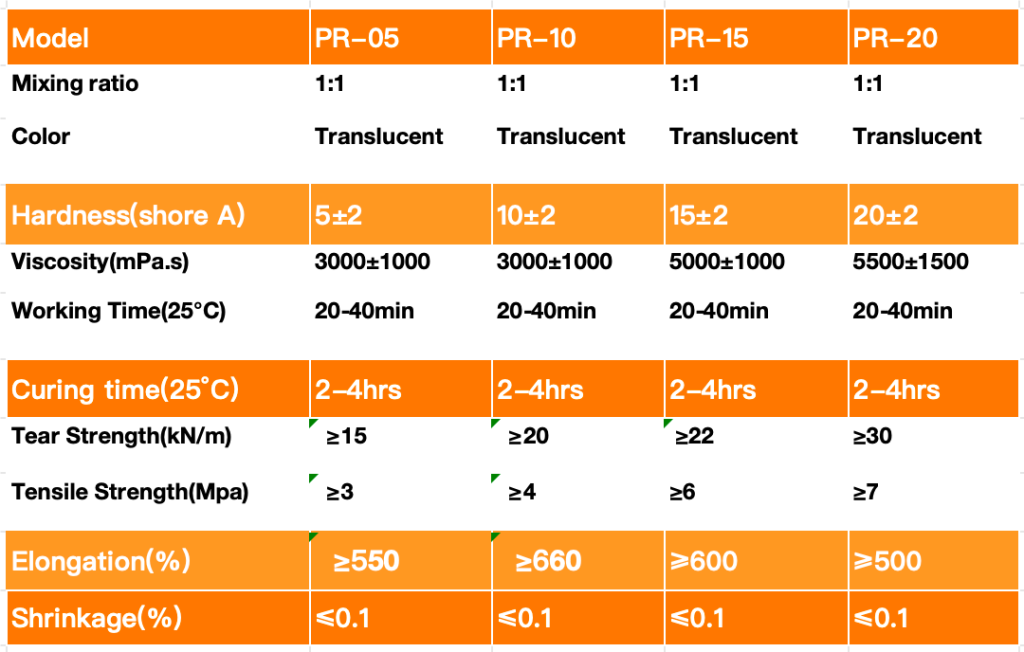

Technical Specifications and Usage Instructions

Technical Specifications

Usage Instructions

- Prepare Your Design: Ensure your mold is clean and free from debris.

- Apply Mold Release Spray: For easier demolding, apply a mold release spray to the mold.

- Mix Silicone Components: Combine the liquid silicone components according to the specified mix ratio.

- Pour Silicone: Carefully pour the silicone mixture into the mold, ensuring complete coverage to form the flesh tone prosthetic component.

- Cure: Allow the silicone to cure at room temperature for the recommended period.

- Demold: Gently remove the silicone prosthetic component from the mold, ready for user application.

Environmental Impact and Sustainability

Our manufacturing processes prioritize sustainability and environmental responsibility. Our silicone prosthetics are designed to last, reducing waste and the frequency of replacements. Further, our products are developed using eco-friendly materials and methods to minimize environmental impact.

- Recyclable Materials: Contribute to a sustainable future with our fully recyclable silicone products.

- Energy-Efficient Production: Advanced technologies reduce our carbon footprint and conserve energy during production.

- Low VOC Emissions: Maintain a safer environment with minimal volatile organic compound emissions during curing.

Customer Reviews

“Using platinum silicone for our prosthetics has elevated our product line. The comfort and durability are unmatched, resulting in positive feedback from our users.”

— Evan R., Prosthetic Products Manufacturer

“Their silicone elastomers have made mold making easier and more detailed. Our silicone prosthetics are more lifelike and durable than ever before.”

— Hamed S., Orthotic Factory Specialist

“As a prosthetic manufacturer, we require materials that deliver flexibility and ease of use. This silicone has been a game-changer for our company.”

— David K., Prosthetic Factory Manager

Comparing Silicone Prosthetics Materials

| Feature | Silicone | Foam | Latex |

|---|---|---|---|

| Durability | Excellent | Moderate | Low |

| Flexibility | Superior | Good | Limited |

| Realism | High | Moderate | Moderate |

| Chemical Resistance | Excellent | Low | Poor |

| Eco-Friendliness | High | Moderate | Low |

| Skin Safety | Very Safe | Less Safe | Possible Irritation |

| Customization | High | Low | Low |

Advantages from the Customer’s Perspective

Enhance your product line with durable, flexible, and eco-friendly silicone prosthetics, offering superior realism and comfort that aligns with user needs.

For more information on our silicone for prosthetics, visit our Silicones for Prosthetic Application page or explore our RTV Silicone offerings. Discover how our Silicone Rubber can enhance your prosthetic manufacturing processes. Contact our Sales and Support team today to discuss your specific needs and elevate your prosthetic products with our premium silicone solutions.

Table: Silicone Prosthetics Benefits Comparison

| Feature | Silicone Prosthetics | Traditional Prosthetics |

|---|---|---|

| Durability | Very High | Low |

| Comfort | Superior | Moderate |

| Support | Excellent | Limited |

| Eco-Friendly | High | Low |

| Cost Over Time | Lower Long-Term Costs | Higher Due to Replacements |

| Customization | High | Low |

List: Benefits of Choosing Our Silicone Prosthetics

- Unmatched Flexibility: Ensures a comfortable and natural fit for users.

- High Durability: Maintains integrity and performance over time.

- Realistic Aesthetics: Provides a natural look that users appreciate.

- Eco-Friendly Materials: Supports sustainable production practices.

- Custom Options: Tailored to meet specific user needs and improve quality of life.

- FDA Compliant: Ensures safety and reliability in all applications.

Quote:

“The precision and quality of your silicone prosthetics have significantly enhanced our product offerings. Our users report greater satisfaction and comfort.”

— Mark D., Prosthetic Factory Expert

Chart: Prosthetic Material Comparison

EXTProsthetic Material Features

Durability (Scale)

100 ┤

80 ┤

60 ┤█████████████████ Silicone

40 ┤████████████ Foam

20 ┤████ Latex

└──────────────────────────────────────

Silicone Foam Latex

Our silicone prosthetics consistently outperform other materials in durability and flexibility, ensuring your products remain reliable and effective over extended use.

Ready to revolutionize your prosthetic manufacturing with our advanced silicone solutions? Contact us today to discuss your specific requirements and discover how our premium silicone products can elevate your prosthetic offerings.

Summary of Advantages:

Enjoy durable, realistic, and customizable silicone prosthetics that enhance comfort and quality of life, meeting the demands of modern prosthetic manufacturing.